Linked Things launches IIoT Platform for Effective IR4.0 Transformation

Linked Things launches IIoT Platform for Effective IR4.0 Transformation

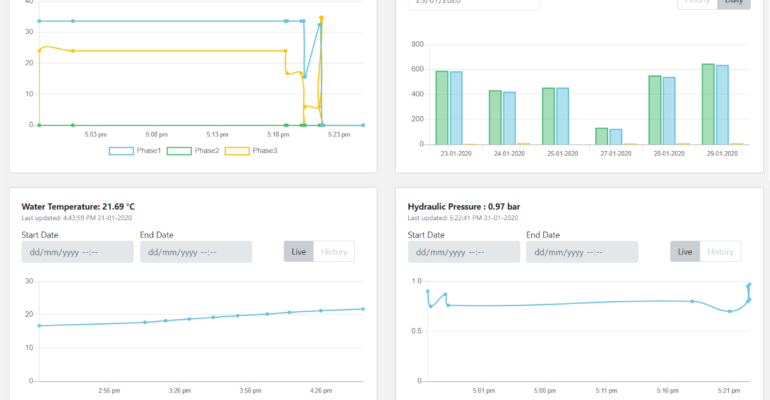

Pakistan has 6000 plastic goods manufacturers employing roughly 600,000 persons. Injection molding is a basic plastic manufacturing operation requiring tremendous amount of electrical energy per unit produced. Each machine can produce hundreds of units per day – running continuously. Recently the new machines being introduced are IIoT or Industrie 4.0 ready. This means that real time data can be acquired from these machines and processed to analyze predictive maintenance requirements. However the industry specially in emerging markets like Pakistan have already invested in machines and replacement is a huge cost. Linked Things’ solution provides a cost-effective way to upgrade the machines. The solution has complete power and machine health monitoring such as 3 phase current consumption, hydraulic pressure, noise detection, water temperature, oil temperature, panel temperature and flow monitoring. The biggest benefit is calculation of per unit energy costs. Together this data gives you complete picture of an operation. Now the industry has capability to identify failures, increase MTBF, reduce down times and above all predict maintenance requirements.